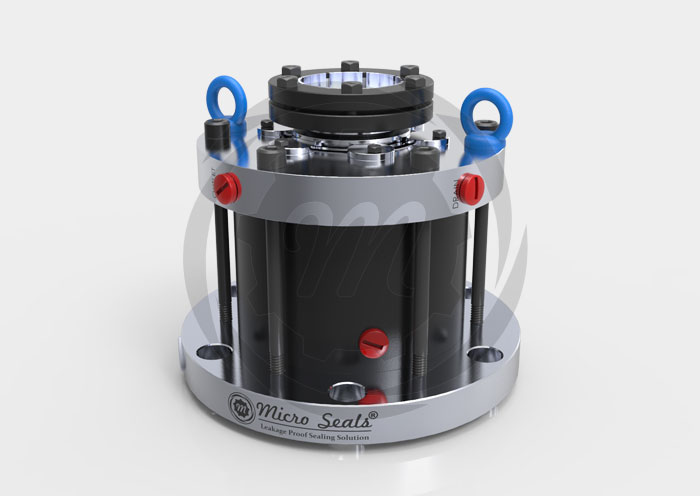

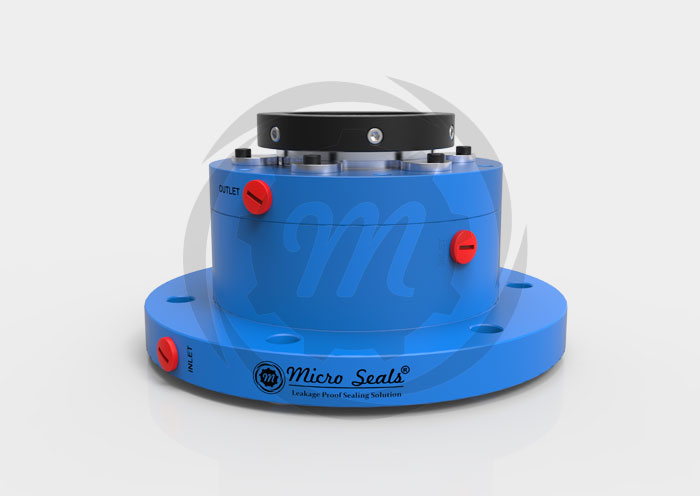

Agitator Reactor Double Mechanical Seals

Agitator / reactor seal is engineered under the firm direction of experienced quality controllers. These are available in various range and technical specifications as per the precise demands and requirements. The entire range is engineered using best available techniques and following international industrial standard. These are widely recommended by clients owing to its precise design and robustness.

Agitator Reactor Double Mechanical Seals

(TYPE GW60/GW61B )

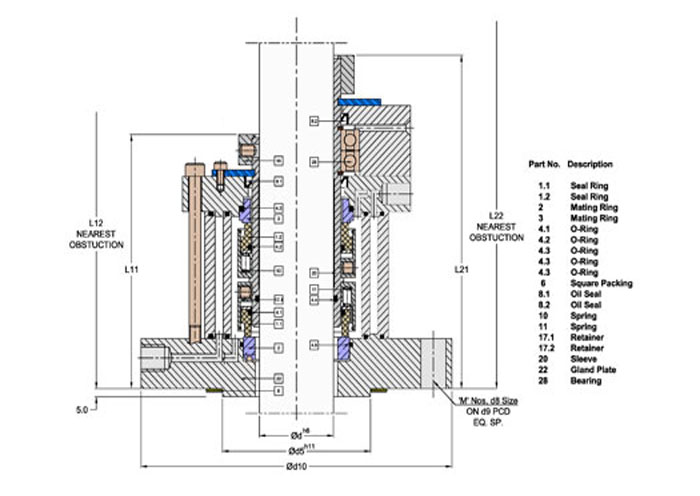

Compact Economical Cartridge Double Mechanical Seal for Agitators and Reactors. Design Incorporate with location of Bearings very close to the Seal. These Seal specially designed for any mixed and pressurized liquid in Vessel with Top Entry Agitators where no leakage in Process Gas OR Fluids to the Environment can be tolerated. Complete Pre-assembled Tested Unit ready for installation. These Seal are used for Exclusive Solid Seal Faces, Stationary Seats, thus Lowest Level of Seal Face distortion when Expose to Compressive Load and Thermal Pressure.

Balance Pusher Seals using for Sealing Environment.

Double Seals are excellent with Low RPM Operation in Full Vacuum and Pressure.

Chemical industry, Petrochemical industry, Pharmaceutical industry, Food and beverage industry, Non-toxic media, Agitators, Mixers, Reactor

- Pressure :Full Vacuum to 10 bar

- Temperature :-20oC to 220oC

- Speed : 400 r.p.m.

- Size : 40mm to 150mm

- Seal Ring Face : Carbon and SiC, Tc

- Mating Ring Face : SiC, Tc

- Secondary Seals : Elastomer PTFE

- Metal Parts : SS316