Mechanical Seals for the Water and Wastewater Industry

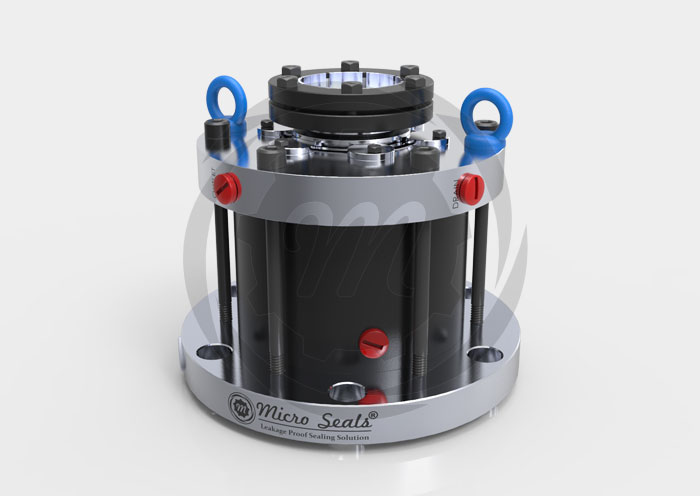

The water and wastewater treatment industry demands reliable and durable mechanical seals to ensure the seamless operation of pumps, mixers, and other rotating equipment. These seals must withstand harsh environments, including exposure to chemicals, abrasive particles, and varying pressures. Mechanical seals in this sector play a critical role in preventing leaks, maintaining efficiency, and reducing environmental impact.

Applications in the Water and Wastewater Treatment Industry

Mechanical seals are indispensable in various applications, including:

- Pumps: Ensuring leak-free operation in water transfer, sludge handling, and chemical dosing pumps.

- Mixers and Agitators: Reliable sealing for mixing chemicals and aeration processes.

- Aerators: Preventing leakage and ensuring efficient oxygen transfer.

- Centrifuges: Seals that handle high speeds and abrasive materials during sludge separation.

- Valves: Ensuring tight sealing in flow control systems.