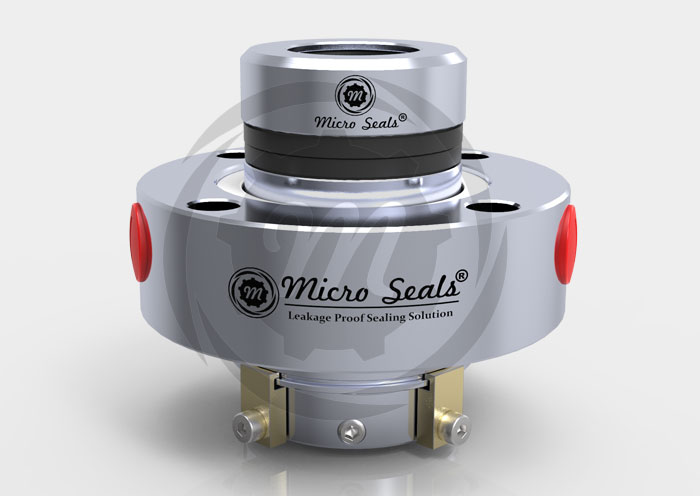

Mechanical Seals for Chemical Industry or Chemical Plant

The chemical industry demands high-performing, reliable equipment, to handle complex processes involving aggressive, corrosive, and hazardous substances. Mechanical seals are a crucial component in maintaining safety, efficiency, and environmental compliance. They are used extensively in pumps, mixers, and reactors to prevent leakage, ensuring process stability and workplace safety.